Reversible Plastic Pallets

Discover the unparalleled versatility and robustness of our Reversible Plastic Pallets, expertly crafted to cater to the diverse requirements of your business.

Enlightening Electromechanical's Product Range: Reversible Plastic Pallets

Enlightening Electromechanical, a leader in the plastic pallet industry, is proud to offer an innovative range of Reversible Plastic Pallets, designed for diverse industrial needs. Our product range is categorized into two main types: Reversible Grid Plastic Pallets and Reversible Flat Top Plastic Pallets.

Reversible Grid Plastic Pallets

Ideal for heavy-duty use in industries like pharmaceuticals and food and beverages. They are made from UV stabilized HDPE and designed for high load capacities, offering durability and easy cleaning.

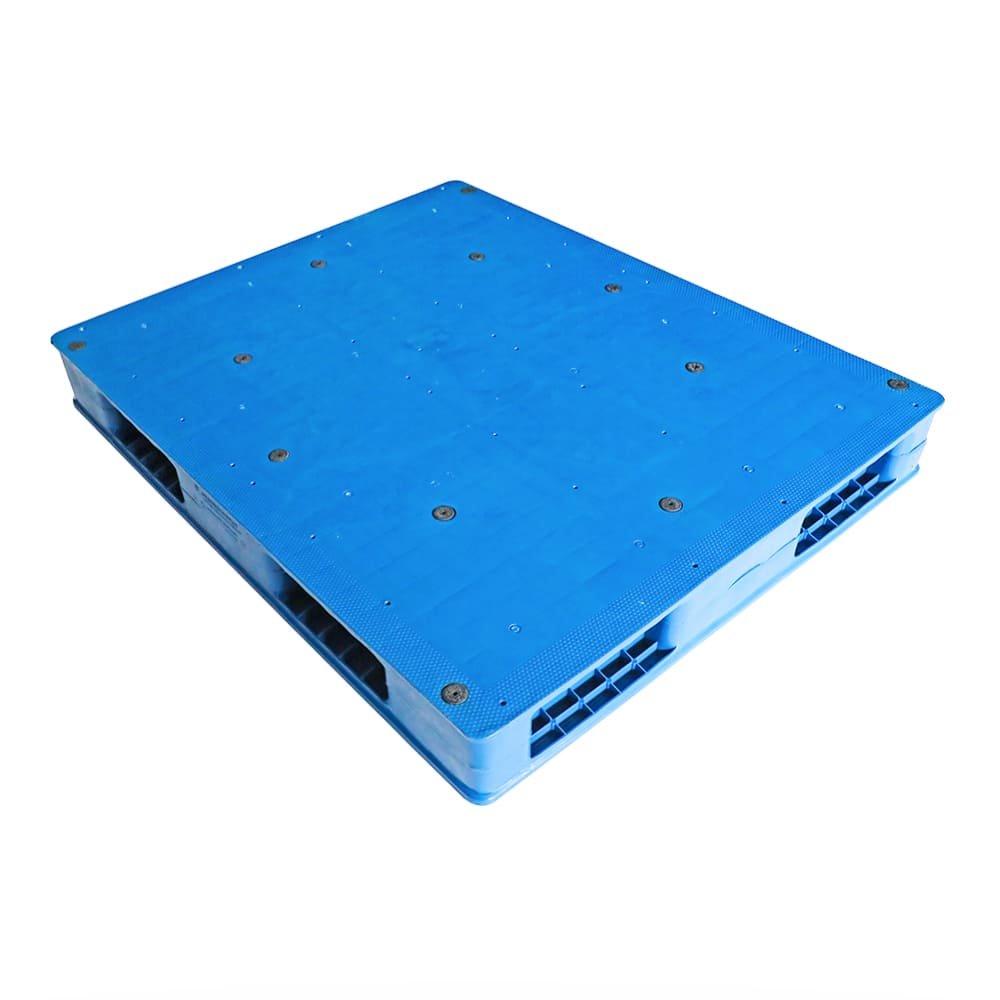

Reversible Flat Top Plastic Pallets

Suitable for diverse applications including warehouse stacking and cargo transfer. These pallets feature a flat top design for stable stacking and are capable of handling significant static and dynamic loads.

Enlightening Electromechanical offers two core models of reversible plastic pallets, catering to diverse storage and transportation needs. These models are optimized for specific applications and can be customized for unique requirements.

Both models from Enlightening Electromechanical are a testament to our commitment to delivering quality, eco-friendly, and durable solutions, backed by experienced manufacturers and suppliers. These reversible plastic pallets are designed to integrate seamlessly into your logistics and storage processes, with options for customization to meet specific operational needs.

Get Your Free Plastic Pallet Catalog Today!

Discover a range of durable and sustainable plastic pallets in our catalog. From heavy-duty to export and food-grade options, find the perfect solution for your logistics needs. Request your free catalog today for efficient, eco-friendly pallet choices.

Why Enlightening Electromechanical is Your Ideal Reversible Plastic Pallet Partner

Enlightening Electromechanical stands out as a leading supplier of reversible plastic pallets, offering innovative solutions tailored to diverse industry needs.

Innovative Reversible Plastic Pallets:

- Material: Made from new HDPE and PP, ensuring durability and longevity.

- Design: Our pallets feature a reversible design, making them versatile for various applications. They are available in both grid and flat-top models, suitable for heavy-duty use and efficient stacking in industries like electronics, petroleum, food, pharmaceutical, and more.

- Customization: We offer custom-made sizes to match specific operational requirements.

Advanced Manufacturing:

- Technology and Quality: Leveraging cutting-edge manufacturing technology, our pallets are robust, weather-resistant, and maintenance-free.

- Production Facilities: With extensive production capabilities, we ensure a consistent supply of high-quality pallets.

Industry-Wide Applications:

- Versatility: Our pallets are suitable for a wide range of industries, including pharmaceutical, medical, and food applications. They are ideal for export due to their stackable and durable nature.

Customer-Centric Approach:

- Tailored Solutions: Understanding that each client has unique needs, we specialize in providing custom solutions.

- Global Reach: As one of the largest plastic pallet manufacturers and suppliers, we offer comprehensive services, including OEM & ODM.

Competitive Pricing:

- Value for Investment: Our pallets are competitively priced, offering the best value for quality and functionality.

Enlightening Electromechanical’s commitment to innovation, quality, and customer satisfaction makes us the ideal partner for your reversible plastic pallet needs. Whether for heavy-duty industrial use or efficient storage and transport, our pallets are designed to seamlessly integrate into your logistics processes.

Your Comprehensive Guide to Reversible Stacking Plastic Pallets

Reversible stacking plastic pallets are essential in modern logistics, offering versatile solutions for storage and transportation. Here’s why they are ideal for your operations:

What is the Reversible Plastic Pallets ?

Our Reversible Plastic Pallets, crafted by top plastic pallet manufacturers, are designed for heavy-duty use. These dual-sided pallets provide versatile, durable solutions for diverse industrial needs. Ideal for sectors such as food, medicine, and logistics, they are eco-friendly and maintain high standards of hygiene and strength. Perfect for businesses prioritizing robust, sustainable, and efficient material handling solutions.

Additionally, these heavy-duty plastic pallets are built to ensure long-lasting performance, reducing the need for frequent replacements. This not only saves on costs but also aligns with eco-friendly practices. They are a smart choice for companies looking to balance quality, cost, and environmental responsibility in their operations.

Brief History of Plastic Pallets

The narrative of reversible plastic pallets, revolutionized by leading plastic pallets manufacturers, began its ascent post-World War II. This era marked a transformative shift in the logistics materials landscape. Visionaries like Fred Robinson catalyzed the initial development, with the advent of injection-molded plastic pallets in the 1960s heralding a significant advancement. The 1970s saw these pallets, especially heavy-duty plastic pallets, gain substantial momentum. Their lightweight, durability, and environmental resistance made them preferable over traditional wooden pallets.

This period underscored a growing inclination towards plastic over wood, spurred by the demand for more efficient, sustainable logistics solutions. The shift to plastic pallets signified a critical evolution in the supply chain, enhancing handling and storage capabilities. Today, as a testament to ongoing innovation in material technology, reversible plastic pallets continue to play a pivotal role in global logistics, representing the ingenuity and progress championed by top plastic pallet manufacturers.

Advantages of Reversible Plastic Pallets

Advantages of Reversible Plastic Pallets

Explore the significant benefits of Reversible Plastic Pallets, an innovative solution in logistics and supply chain management. These pallets, crafted by top-tier plastic pallets manufacturers, are readily available for sale and are designed for heavy-duty performance.

- Enhanced Durability and Longevity: These pallets surpass traditional wooden pallets in lifespan, withstanding rigorous use while retaining their structural integrity.

- Superior Load Handling and Stability: Their specialized design ensures optimal stability and even weight distribution, providing a secure platform for various types of cargo.

- Lightweight and Cost-Effective in Transportation: The lighter weight of these pallets translates to lower energy consumption during transport, potentially reducing freight costs.

- Eco-friendly Composition: Constructed from high-density polyethylene (HDPE) and polypropylene (PP), these pallets are not only sturdy but also contribute to sustainable supply chain practices.

- Cost-Efficiency Over Time: Despite a higher initial cost, the durability and reusability of these pallets lead to significant long-term savings.

- Hygienic and Easy to Clean: Resistant to moisture, chemicals, and pests, these pallets maintain high hygiene standards, suitable for industries like food and pharmaceuticals.

- Aesthetically Pleasing and Customizable: They come in various designs, allowing for customization to suit branding needs, enhancing the visual aspect of logistics.

- Operational Efficiency: The design of these pallets simplifies handling and storage, reducing labor and time in logistics and warehouse operations.

Reversible Plastic Pallets, with their range of benefits, stand as a preferred choice in modern logistics, offering durability, efficiency, and eco-friendliness. Their availability from renowned plastic pallets manufacturers ensures a blend of quality and functionality for diverse industrial needs.

Design Guide for Reversible Plastic Pallets

Our expertise in designing Reversible Plastic Pallets is tailored to meet the diverse needs of various industries. We offer high-quality, versatile pallets from leading plastic pallets manufacturers, focusing on efficient design and robust functionality. These pallets are ideal for organizations prioritizing plastic pallets recycling, seeking stackable solutions, and requiring reliable plastic pallets suppliers.

- Reversible Grid Plastic Pallets: These pallets are characterized by a grid-pattern top deck, ensuring excellent ventilation and drainage. This design is particularly beneficial for sectors requiring stringent hygiene, such as food and pharmaceutical industries. The grid structure minimizes material use, balancing lightness with strength.

- Reversible Flat Plastic Pallets: With a flat top deck, these pallets provide a consistent and stable surface, ideal for various goods. Their solid design increases load-bearing capacity, suited for heavier items and high-rack storage.

Both grid and flat variants of our Reversible Plastic Pallets feature a robust support structure for even load distribution and enhanced stability. Our design philosophy includes:

- Robust Durability and High Load Capacity: Constructed from durable materials, these pallets are built to handle heavy loads and frequent usage.

- Customization Flexibility: Tailoring dimensions and colors to fit your specific branding and logistical needs is part of our service.

- Efficient and Space-Saving Design: The design of these pallets promotes easy handling and effective stacking, optimizing space in storage and transport.

Partner with us to discover how our Reversible Plastic Pallets can revolutionize your supply chain management. As a leading plastic pallets supplier, we are committed to delivering solutions that enhance both efficiency and sustainability in your logistics and storage operations.

How to Choose the Best Reversible Plastic Pallets for Your Business

When selecting the ideal Reversible Plastic Pallets, it’s crucial to consider various factors to ensure they align with your specific operational requirements. Whether you’re looking for heavy-duty plastic pallets from a reputable plastic pallets manufacturer, affordable plastic pallet prices from a reliable plastic pallets supplier, or exploring eco-friendly options like pallet plastik Bandung, these guidelines will help:

- Purpose and Usage: Determine the primary use of the pallets. Choose between reversible grid pallets for industries needing ventilation (e.g., food or pharmaceuticals) and flat pallets for stable transportation of uniformly shaped goods.

- Load Capacity: Assess the weight and type of items to be transported. Each pallet design offers different load capacities, suitable for either heavier or lighter goods.

- Compatibility with Automated Systems: In today’s automated logistics environment, check if the pallets are compatible with systems like Automated Guided Vehicles (AGVs). Look for features such as embedded tracking capabilities.

- Sustainability and Eco-friendliness: Opt for pallets made from recyclable or biodegradable materials if reducing environmental impact is a concern. Sustainable pallets are durable, withstand heavy loads, and endure extreme temperatures.

- Durability and Maintenance Needs: Evaluate the expected lifespan and maintenance requirements of the pallets. Plastic pallets generally last longer and require less upkeep than wooden ones, providing long-term cost savings.

- Hygiene and Safety Standards: Important for industries like food and pharmaceuticals, choose pallets that are easy to clean and sanitize to minimize contamination risks.

- Size and Storage Efficiency: Consider your storage and transportation space. Nestable plastic pallet designs are ideal for space-saving.

- Cost-Effectiveness: While the initial investment in plastic pallets might be higher, their long-term durability and reusability often lead to cost savings.

By taking these factors into account, you can make an informed decision on the best type of Reversible Plastic Pallets for your business. This ensures safety, durability, efficiency, and sustainability in your operations. For the best deals, explore various options in plastic pallet prices and seek out a trusted plastic pallets supplier or manufacturer.

Understanding Pricing for Reversible Plastic Pallets

When considering the purchase of Reversible Plastic Pallets, understanding the pricing involves several factors. This guide helps you navigate through the aspects influencing the cost, whether you’re dealing with manufacturers, suppliers, or checking plastic pallet prices in specific markets like pallet plastik Bandung.

Material Quality: The choice of materials like HDPE and PP affects durability and functionality, thus impacting the price.

Manufacturing Techniques: Different production methods, including thermoforming and injection molding, vary in cost due to their distinct processes and outcomes.

Design Specifications: The pallet’s size, weight capacity, and design intricacies like grid or flat surfaces play a role in the cost. Tailored designs meeting industry standards can also add to the price.

Volume of Purchase: Ordering in bulk can lead to reduced costs per unit due to economies of scale, while smaller orders might incur higher prices.

Market Dynamics: The pricing is influenced by market demand and supply, where high demand and limited supply can hike prices, and vice versa.

Additional Features: Custom features like anti-slip surfaces or RFID tags enhance functionality but can increase the cost. Assess these features based on industry needs.

In summary, the pricing of Reversible Plastic Pallets is multifaceted. It’s shaped by material quality, manufacturing methods, design specifics, order volume, market trends, and additional custom features. Understanding these factors ensures you make a well-informed decision, balancing cost-effectiveness with functional requirements.

Advanced Manufacturing Techniques for Reversible Plastic Pallets

Discover how Reversible Plastic Pallets are crafted, a process combining innovation and efficiency. These pallets are essential in various sectors, from logistics to retail, and their production involves state-of-the-art techniques by leading plastic pallets manufacturers and suppliers.

Injection Molding: A favored method for mass production, injection molding transforms PP or HDPE into durable pallets. Raw materials are melted and injected into molds, creating strong pallets with detailed designs. While effective, this method is known for its higher energy consumption.

Low Pressure Structural Foam Molding: This technique mixes plastic with an inert gas, producing pallets with an impressive strength-to-weight ratio. It’s an economical choice, offering design flexibility and requiring less material.

Thermoforming: Involves heating plastic until it’s malleable, then shaping it over a mold. Thermoforming, which includes vacuum and pressure forming, allows for versatile design options. Pressure thermoforming is particularly suited for intricate designs.

These processes ensure the production of high-quality Reversible Plastic Pallets, balancing strength, design complexity, and cost-efficiency. They are integral in meeting diverse industry needs, offering robustness and versatility.

Material Selection for Reversible Plastic Pallets

Understanding the choice of materials for Reversible Plastic Pallets, especially for heavy-duty and export applications, is key to ensuring their durability, functionality, and cost-efficiency. Here’s an overview of the materials commonly utilized by plastic pallet manufacturers:

Polypropylene (PP): PP is chosen for its lightweight yet robust characteristics, ideal for pallets that need to be maneuverable. It offers excellent resistance to chemicals and moisture, making it suitable for harsh conditions.

High-Density Polyethylene (HDPE): HDPE stands out for its strength, rigidity, and impact resistance, perfect for pallets bearing heavy loads. Its versatility comes from its resistance to various chemicals and moisture.

Polyolefin: This material blends PP and HDPE, combining their advantages – lightweight, strength, and durability. It’s a cost-effective option, moldable into diverse shapes and sizes, and resistant to chemicals and moisture.

Fiberglass: Selected for its strength, lightness, and corrosion resistance, fiberglass is used in pallets required to withstand high temperatures or harsh chemicals, ideal for industries like food or pharmaceuticals.

Recycled Plastics: Using recycled plastics aligns with environmental sustainability efforts, offering a balance between eco-friendliness and quality performance.

For Heavy-Duty Plastic Pallets, materials like HDPE, PP, and fiberglass are preferred for their robustness, durability, and chemical resistance, ensuring they endure the demands of intense usage and shipping.

The manufacturing process, including advanced techniques like injection molding, transforms these materials into Reversible Plastic Pallets with superior stability, load capacity, and resistance to impacts or deformation.

Why Opt for Reversible Plastic Pallets from Enlightening Electromechanical?

Selecting Enlightening Electromechanical for your Reversible Plastic Pallets needs guarantees access to products crafted from premium materials like HDPE, PP, and fiberglass. As a reputable manufacturer, Enlightening Electromechanical is renowned for its ability to tailor solutions that meet your exact specifications.

Our products stand out for their durability, high quality, and commitment to sustainability and customer satisfaction.

Choosing Enlightening Electromechanical means you’re not just purchasing a product; you’re investing in pallets that excel in functionality, eco-friendliness, and meet the highest standards of industrial excellence.

Comparative Benefits of Reversible Plastic Pallets Versus Wooden Pallets

Advantages of Reversible Plastic Pallets:

- Durability and Longevity: Constructed from materials like HDPE and PP, these pallets are highly durable. They withstand heavy loads and harsh conditions, offering a longer lifespan and proving to be economical over time.

- Hygiene and Easy Cleaning: Plastic pallets, unlike wooden ones, don’t absorb moisture and resist bacteria. This makes them suitable for industries requiring strict hygiene, like food and pharmaceuticals. Their non-porous surfaces are easy to clean and sanitize.

- Cost-Effectiveness: Initially more expensive, Reversible Plastic Pallets tend to be more cost-effective in the long run due to their longevity and low maintenance needs. Additionally, being often recyclable, they have a reduced environmental impact.

- Lightweight and Space Efficiency: Plastic pallets are lighter, reducing handling injuries and improving transport efficiency. Many are also nestable, saving space in storage.

- Environmental Benefits: The use of recyclable materials in Reversible Plastic Pallets lessens their environmental footprint.

Disadvantages of Reversible Plastic Pallets:

- Load Sensitivity: They may be less capable of handling extremely heavy loads repeatedly compared to wooden pallets and are not as easily repairable.

- Energy-Intensive Manufacturing: Producing plastic pallets consumes more energy and resources, contributing to environmental concerns.

- Non-Biodegradability: Most plastic pallets don’t biodegrade, raising issues regarding plastic waste and its environmental impact.

- Potential Chemical Risks: Some plastic pallets may contain chemicals that could leach into products.

In conclusion, Reversible Plastic Pallets from reputable manufacturers and suppliers in the plastic pallet industry offer benefits like durability, hygiene, and efficiency, but considerations regarding environmental impact and load capacity are essential.

Industries Utilizing Reversible Plastic Pallets

Reversible Plastic Pallets, known for their robustness, adaptability, and eco-friendly nature, are widely used across multiple sectors. Prominent industries leveraging these pallets, manufactured by leading plastic pallets manufacturers and suppliers, include:

Automotive Industry: Capitalizing on the strength and lightweight characteristics of these pallets, the automotive sector utilizes them for the efficient handling of heavy parts and machinery. Their customizability and compatibility with automated systems add to their appeal in this industry.

Chemical Industry: The chemical resistance and weatherproof qualities of Reversible Plastic Pallets make them the top choice in the chemical industry. Their non-absorbent nature is crucial for the safe handling and transportation of sensitive chemical products.

Food and Beverage Industry: The hygienic and contamination-resistant properties of these pallets are essential in food and beverage operations, where cleanliness and food safety are paramount.

Pharmaceutical Industry: In an environment where strict hygiene and contamination prevention are critical, the non-porous, easily sanitized surfaces of these pallets are greatly valued.

Petroleum and Lubricant Industry: These pallets provide a protective barrier against environmental factors, ensuring the safe transportation of petroleum and lubricant products.

Key benefits for these industries include the pallets’ versatility in accommodating various plastic pallets sizes and their contribution to the economy as cost-effective solutions. Reversible Plastic Pallets have become integral in these sectors, aligning with global trends towards sustainability and environmental responsibility

Precautions for Handling and Use of Reversible Plastic Pallets

Implementing best practices when handling Reversible Plastic Pallets is essential for ensuring safety, preserving their condition, and maximizing their lifespan. These guidelines are crucial for various industries, including those using heavy duty plastic pallets and products from plastic pallets suppliers or plastic pallets bunnings.

Selecting the Appropriate Pallet: It’s vital to choose a pallet based on the type and weight of the load. Reversible Plastic Pallets come in different weight capacities and are designed for specific types of goods.

Pallet Inspection and Preparation: Before use, check each pallet for damages like cracks or breakages. Clean the pallet to prevent contamination and place it on a flat, stable surface for safe loading.

Even Weight Distribution: When stacking items, distribute the weight evenly across the pallet. Heavier items should be loaded first, at the bottom, and consider using interlocking layers for stability during transport.

Securing the Load: Utilize materials like plastic wrap or stretch film to secure the goods on the pallet. The wrapping should be tight enough to hold items in place but not so tight as to cause damage.

Wrapping for Storage or Transport: Opt for strong, durable wrapping materials appropriate for the load’s weight. Wrap the pallet thoroughly at the base, sides, and top, ensuring each layer overlaps for added stability.

Storing Unused Pallets: Store unused pallets in a dry, clean, and ventilated area. Protect them from direct sunlight, extreme temperatures, and moisture to retain their structural integrity.

Following these precautions is vital for anyone using Reversible Plastic Pallets, whether they are sourced from plastic pallets manufacturers, suppliers, or stores like Bunnings. Proper handling and maintenance ensure these pallets remain a reliable and efficient resource in logistics and storage operations.

Cleaning and Maintenance of Reversible Plastic Pallets

Proper cleaning and maintenance of Reversible Plastic Pallets are essential to ensure their longevity, hygiene, and optimal performance. Follow this step-by-step guide:

Remove Loose Debris: Begin by using a broom or brush to clear any loose dirt or debris from the surface of the pallets.

Cleaning Solution: Prepare a cleaning solution using a mild detergent or disinfectant cleaner that is suitable for plastic materials. Always follow the manufacturer’s guidelines for the product.

Application: Apply the cleaning solution evenly across the pallets using a spray bottle or a suitable method, making sure that all surfaces are adequately covered.

Scrubbing: Use a soft brush or scrub pad to gently scrub the cleaning solution onto the surface of the pallets, paying extra attention to areas with stains or dirt buildup.

Rinsing: Thoroughly rinse the pallets with clean water to remove all traces of the cleaning solution. If using a pressure washer, ensure that the pressure is at a level that won’t cause damage to the pallets.

Drying: Allow the pallets to air dry completely before stacking or putting them to use. Avoid stacking damp or wet pallets, as this can promote the growth of mold and other microorganisms.

Dos and Don’ts:

Do: Use a soft brush or pad to prevent scratching the pallets and ensure that all cleaning solutions are entirely rinsed off. It’s recommended to clean the pallets regularly based on usage frequency and environmental exposure.

Don’t: Avoid using high-pressure water jets, bleach, or harsh chemicals that can degrade plastic materials. Never stack damp or wet pallets, as this can create an environment conducive to mold and microorganism growth.

For all your Reversible Plastic Pallets maintenance needs, you can trust Enlightening Pallet, one of the leading plastic pallets manufacturers and suppliers. Our heavy-duty plastic pallets are designed for durability and hygiene. Contact us for high-quality plastic pallets that meet your specific requirements. Whether you are in need of plastic pallets for industrial or commercial use, Enlightening Pallet has you covered. Explore our range of plastic pallets today!

Applications of Plastic Pallets Across Diverse Industries

Plastic Pallets, available in specialized varieties such as Plastic Freezer Pallets and HDPE Logistic Plastic Pallets, find extensive utility across a diverse spectrum of industries. Their unique features and advantages make them indispensable in various applications. As a trusted plastic pallets manufacturer and supplier, Enlightening Pallet delivers solutions that cater to these industries’ specific needs.

Logistics and Supply Chain

Essential for efficient and economical transportation and warehousing.

Food and Chemical Industries

Preferred for their heat dissipation and impact resistance, ensuring safe transport of sensitive goods.

Warehouse Storage

Rackable pallets cater to heavy-duty storage needs with high load capacities.

Choosing the Right Reversible Plastic Pallets Manufacturer or Supplier

electing the ideal manufacturer or supplier for Reversible Plastic Pallets is a critical decision that can impact your business’s efficiency and success. Here are essential considerations to guide your selection:

Industry Certifications: Prioritize suppliers with industry certifications such as ISO9001. These certifications indicate a commitment to quality and regulatory compliance in the production of plastic pallets.

Product Range: Look for suppliers who offer a diverse range of Reversible Plastic Pallets. A wide product range demonstrates their expertise and ability to meet various industry-specific needs, including Heavy Duty Pallets and Plastic Pallets for Racking Usage.

After-sales Support: Choose a supplier that provides robust after-sales support. This includes assistance with maintenance, repairs, and replacements, ensuring your long-term satisfaction with their products.

Safety Standards: Verify that the supplier’s plastic pallets comply with safety regulations and industry standards. Ensuring the safety of your products and employees is paramount.

Reputation and Reviews: Assess the supplier’s reputation by seeking feedback from existing customers and requesting references. Positive reviews and testimonials are indicative of a reliable supplier.

Technical Expertise: Evaluate the supplier’s technical knowledge and expertise. They should be able to guide you in selecting the most suitable Reversible Plastic Pallets for your specific needs, whether for storage or transportation.

Customization Options: Inquire if the supplier offers customization options. Sometimes, your industry may require pallets with specific dimensions or features. A supplier that can tailor their products to your requirements is valuable.

Transparent Pricing and Communication: Opt for a supplier that provides transparent pricing and effective communication. Avoid suppliers with hidden costs or unclear terms. Clear communication ensures a smooth and efficient partnership.

As a trusted plastic pallets manufacturer and supplier, Enlightening Pallet excels in meeting these criteria. Our range of Reversible Plastic Pallets, including Heavy Duty Pallets and those suitable for Racking Usage, is designed to meet the diverse needs of various industries. With ISO9001 certification, a strong reputation, and a commitment to quality, we are your reliable partner in plastic pallet solutions. Contact us today to discuss your specific requirements and explore our wide range of high-quality plastic pallets.

Get in Touch

Submit Your Inquiry

Connect with us to discuss your plastic pallet needs. Our team is ready to provide solutions tailored to your specific requirements. Whether it’s a question about our products, a request for a quote, or a need for custom solutions, we’re here to assist you.

Elina You

- Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

- +86 187 2476 3201

- sales03@cnplasticpallet.com