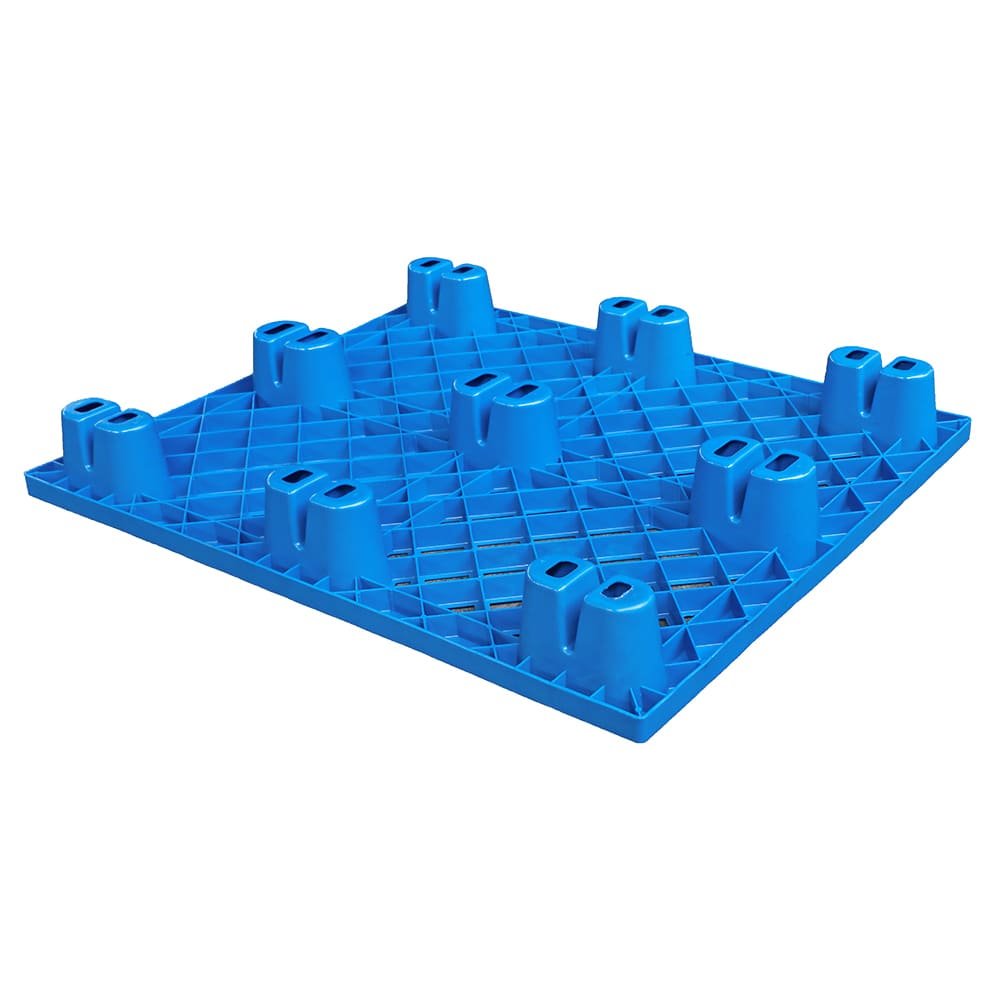

3 skids plastic pallet

Robust and versatile, ideal for heavy-duty applications. Eco-friendly, with efficient handling and storage design.

Enlightening Electromechanical: Diverse Range, Focused Innovation

Enlightening Electromechanical, a leader in the plastic pallet industry, is dedicated to the innovative design and superior manufacturing of high-quality plastic pallets. Our focus on delivering reliable, recyclable, and eco-friendly solutions is embodied in our diverse range of products, serving a global clientele with excellence.

Central to our portfolio is the 3 Skids Plastic Pallet, a testament to our commitment to durability and environmental responsibility.

Our product range is broadly classified into two main categories:

3 skids Grid Plastic Pallets

Enlightening Electromechanical’s 3 Skids Grid Plastic Pallets, made from robust HDPE, feature a grid-top design for secure stacking and handling, support substantial dynamic loads, and are fully recyclable, promoting sustainable operations.

3 skids Flat Plastic Pallets

Durable and seamless, Enlightening Electromechanical’s 3 Skids Flat Plastic Pallets ensure efficient transport with solid HDPE construction. Eco-friendly, they provide a smooth surface for stable, safe load handling.

Enlightening Electromechanical offers two core plastic pallet models: the 3 Skids Grid Plastic Pallet and the 3 Skids Flat Plastic Pallet. Each is designed to cater to specific storage and transportation needs, with features supporting a variety of applications.

We also specialize in tailored solutions for unique requirements. Our expertise enables us to customize pallets beyond these standard models, ensuring they align with your specific operational demands, whether in load capacity, size, or other unique characteristics. Our commitment is to deliver pallets that effortlessly integrate into your logistics and storage systems.

Get Your Free Plastic Pallet Catalog Today!

Discover a range of durable and sustainable plastic pallets in our catalog. From heavy-duty to export and food-grade options, find the perfect solution for your logistics needs. Request your free catalog today for efficient, eco-friendly pallet choices.

Why Enlightening Electromechanical is Your Ideal Plastic Pallet Partner

At Enlightening Electromechanical, we blend innovation with experience to offer top-quality plastic pallet solutions. Our expertise spans across various industries, making us a trusted partner in the global market. We’re known for our commitment to producing eco-friendly, durable, and cost-effective plastic pallets.

- Tailored Solutions for Your Business

We understand every client has unique needs. Our approach is to provide custom-made plastic pallets, ensuring they perfectly align with your specific requirements for efficiency, safety, and sustainability. - Advanced Manufacturing Technology

Leveraging cutting-edge production techniques, our plastic pallets are designed to meet the current and emerging demands of various industries, including food, medicine, logistics, and more.

- Excellence in Production

Our two state-of-the-art production bases are equipped with over 100 specialized machines. This capacity allows us to deliver high-quality plastic pallets that lead the industry in strength and longevity. - Competitive, Transparent Pricing

Offering premium quality doesn’t mean premium prices. Our pallets are priced competitively, ensuring you get the best value for your investment, regardless of your industry size.

Your Comprehensive Guide to 3 Skids HDPE Plastic Pallets

3 Skids HDPE Plastic Pallets are essential in logistics, offering robust platforms for goods in transit and enhancing warehouse storage efficiency. Renowned for their strength, hygienic build, and versatility across diverse environments, these pallets are a key solution in material handling.

What is the 3 Skids Plastic Pallet?

The 3 Skids Plastic Pallet, developed by leading Plastic Pallet manufacturers, is a robust and efficient tool for material handling. Distinguished from the traditional 9 leg Plastic Pallet, it offers exceptional stability and support with its three-skid design. Ideal for industries like food, medicine, and logistics, these pallets guarantee secure storage and transportation of goods without damage. The design of the 3 Skids Plastic Pallet emphasizes smooth handling and consistent performance, making it a vital component in efficient logistics operations. Its construction combines durability, hygienic properties, and eco-friendliness, showcasing the advancements in modern plastic pallet technology.

Brief History of 3 Skids Plastic Pallets

The evolution of plastic pallets, including the 3 Skids model, began after World War II, marking a shift from traditional materials to innovative solutions. Innovators like Fred Robinson contributed significantly in the 1960s, advancing injection molding techniques. By the 1970s, these pallets had gained traction for their durability and versatility. Over the decades, continuous enhancements in design and manufacturing, driven by supply chain evolution, have led to increased performance, strength, and environmental friendliness. Today, 3 Skids Plastic Pallets are a testament to this innovation, offering robust, sustainable, and efficient logistics solutions worldwide. These advancements reflect the dynamic nature of material technology and its critical role in shaping modern supply chain and logistics strategies.

Advantages of 3 Skids Plastic Pallets

3 Skids Plastic Pallets, developed by innovative Plastic Pallet manufacturers, offer numerous benefits in modern logistics and supply chain management:

Durability and Longevity: These pallets are more durable than wooden counterparts, providing a longer lifespan and enduring prolonged use with minimal wear. This translates into significant long-term cost savings despite a higher initial investment.

Load Handling and Stability: The three-skid design ensures optimal stability and even weight distribution, offering a secure platform for various goods. This design is particularly advantageous in automated warehouses, where consistency in pallet dimensions is crucial for smooth operation with automated equipment.

Lightweight and Efficient: Made typically from HDPE, 3 Skids Plastic Pallets are lighter than wood, reducing fuel consumption during transport and allowing more products to be shipped per trip. This efficiency contributes to lower freight costs and a reduced carbon footprint.

Eco-friendly and Recyclable: These pallets are manufactured using recyclable materials like HDPE, significantly reducing lumber waste and emissions associated with wood pallet production. Damaged pallets can be ground up and reformed, minimizing the need for new materials.

Hygienic and Easy to Clean: The non-porous nature of plastic makes these pallets resistant to moisture, chemicals, and pests, making them ideal for industries requiring high hygiene standards, such as food and pharmaceuticals.

Customizable and Aesthetically Pleasing: Available in various designs, 3 Skids HDPE Plastic Pallets can be tailored to specific needs and branding purposes, adding an aesthetic dimension to logistics operations.

Operational Efficiency: The design of 3 Skids Plastic Pallets facilitates easier handling and storage, reducing labor and time in logistics operations. Their compatibility with modern warehouse automation systems makes them a suitable choice for highly automated logistics environments.

3 Skids Plastic Pallets, with their array of advantages, are a preferred choice in logistics, offering innovative solutions that align with the evolving needs of supply chain management.

Design Guide for 3 Skids Plastic Pallets

Our design approach for 3 Skids Plastic Pallets, developed by leading Plastic Pallet manufacturers, is tailored to meet the diverse needs of various industries, offering both durability and versatility:

3 Skids Plastic Pallets Specifications:

- Dimensions typically include a base size of 1000 x 1200mm, with an overall height of 770mm and an internal height of 575mm. The pallets feature three skids along the long dimension, enhancing handling and rotation.

- They are made of high-density polyethylene (HDPE) or recycled material, offering a robust HDPE solid base and sides.

- The pallets are designed to support substantial static and dynamic loads. For example, they can handle a static load of 3 tons and a dynamic load of 1.5 tons, with a racking capacity of 1.2 tons, making them suitable for heavy-duty applications.

- They are available with open or closed top deck options, and multiple color choices are available, particularly in virgin materials.

Design Features for Various Industries:

- The pallets are weather-resistant and easy to clean, ideal for industries requiring high hygiene standards like food, pharmaceuticals, and healthcare.

- For automated logistics and warehouse environments, the pallets offer efficient design features like 4-way entry for fork trucks and pallet jacks, and they are stackable with anti-slide grommets to prevent sliding during transit.

- Optional features like metal rods or removable lids can be added for extra security and protection of the goods.

Customization and Heavy-Duty Needs:

- Our 3 Skids Plastic Pallets are customizable to specific industry or supply chain requirements, including the ability to support various load capacities. Custom built pallets can support a dynamic load capacity and are designed to match exact load capacity needs.

- They are a maintenance-free alternative to wood pallets, with consistent dimensions supporting warehouse automation and operational efficiency.

Engaging with us for your 3 Skids Plastic Pallet needs ensures you receive a product precisely tailored to your operational requirements, enhancing efficiency and productivity in your logistics operations.

Selecting the Right 3 Skids Plastic Pallets

When choosing the ideal 3 Skids Plastic Pallets for your business, consider the following key factors to ensure they align with your specific needs:

Intended Use: Assess the primary application of the pallets. The suitability of 3 Skids Plastic Pallets varies based on their use in storage, shipping, or retail display, with each scenario demanding different size, style, and durability requirements.

Load Requirements: Determine the weight and nature of goods to be handled. The durability and weight capacity of the pallets are critical, especially in heavy-duty applications where sturdier pallets are necessary.

Compatibility with Automation: In automated logistics environments, it’s essential to select pallets compatible with equipment like automated guided vehicles (AGVs). Some pallets may require additional features like RFID tracking for improved logistics management.

Sustainability: Choose pallets made from eco-friendly materials like recycled HDPE if environmental impact is a concern. Sustainable pallets not only reduce environmental footprint but also offer robustness for heavy loads and extreme conditions.

Hygiene and Safety: For industries requiring high standards of cleanliness, like food and pharmaceuticals, opt for pallets that are easy to clean and resistant to contaminants. Plastic pallets generally meet these hygiene and safety standards.

Size and Storage Needs: Consider the size of the products and available storage space. Pallet size should match your logistical requirements, with nestable options being ideal for limited storage spaces.

Budgetary Considerations: While plastic pallets may initially cost more, their durability and reusability often result in lower long-term costs. Assess the cost-effectiveness based on their lifespan and maintenance requirements.

By taking into account these considerations, you can select the most appropriate 3 Skids Plastic Pallets for your operations, ensuring safety, durability, efficiency, and sustainability.

Understanding Pricing for 3 Skids Plastic Pallets

When evaluating the pricing of 3 Skids Plastic Pallets, several factors influence the cost, ensuring they cater to your specific business needs:

Material Composition: Pallets made from premium materials like high-density polyethylene (HDPE) may have a higher cost but offer enhanced durability and functionality. This contributes to their longevity and performance over time, making them a cost-effective option in the long run.

Manufacturing Process: The production method (thermoforming, blow molding, or injection molding) affects the cost. Techniques like injection molding, which provide better uniformity, might come at a higher price but ensure quality and consistency.

Design and Specifications: The size, weight capacity, and specific design elements (e.g., grid or flat surfaces) impact manufacturing costs. Customized designs tailored to industry standards can also elevate the price. However, these customizations often result in pallets that are perfectly suited to particular industrial requirements.

Order Volume: Bulk orders typically result in lower per-unit costs due to economies of scale, whereas smaller orders might carry a higher price tag. The overall size of the order is a significant determinant of the final plastic pallets price.

Type of Pallets: There are various types of plastic pallets, each suitable for specific purposes. Rackable pallets, nestable pallets, export pallets, and display pallets each have different price points, with rackable and heavy-duty models generally being more expensive due to their durability and load-bearing capacity.

Sustainability and Recyclability: Pallets made from recycled materials can be more sustainable and eco-friendly. While they may have a different cost structure, these pallets contribute to a reduced environmental footprint and are an increasingly important consideration for businesses mindful of sustainability.

By considering these factors, Plastic Pallet manufacturers can make informed decisions on the best 3 Skids Plastic Pallets for their operations, balancing cost with functionality, durability, and environmental impact.

Manufacturing Process of 3 Skids Plastic Pallets

The production of 3 Skids Plastic Pallets, utilized by various plastic pallet manufacturers, involves advanced manufacturing techniques, each contributing unique benefits to the final product:

Injection Molding: This process is widely used for its ability to produce durable and intricately designed pallets. It involves melting raw materials like PP or HDPE and injecting them into molds to form the pallet shape. This method is suitable for large-scale production of uniform pallets.

Thermoforming: Here, plastic is heated to a pliable state and formed over a mold, then cooled to retain its shape. Thermoformed pallets are known for their versatility and are commonly used in various supply chain applications. This process allows for the production of pallets with detailed designs and is less material-intensive compared to injection molding.

Blow Molding: In blow molding, plastic material is melted and formed into a parison (a tube-like piece of plastic). This parison is then clamped into a mold, and air is blown into it to expand and take the mold’s shape. Pallets made through blow molding are resistant to very low temperatures, have excellent impact resistance, and are lightweight yet strong. This method is often chosen for special orders requiring these specific characteristicsThese manufacturing processes collectively enable the creation of high-quality 3 Skids Plastic Pallets, suitable for a range of industrial applications and environments. The choice of manufacturing technique depends on the specific pallet requirements, including strength, durability, design complexity, and cost considerations.

Material Selection for 3 Skids Plastic Pallets

Choosing the right materials for manufacturing 3 Skids Plastic Pallets, including those used for heavy-duty and export purposes, is essential for ensuring their durability, functionality, and cost-effectiveness. Key materials commonly used in their production include:

High-Density Polyethylene (HDPE): Widely used for its versatility, cost-effectiveness, and strength, HDPE offers high impact resistance and is suitable for pallets needing to withstand heavy loads, shocks, and environmental stresses. It’s compatible with most chemicals and has good corrosion and heat resistance.

Polypropylene (PP): PP is known for its rigidity and strength, making it more durable than HDPE. It’s particularly effective against forklift and pallet jack abuse and is chemically resistant. However, PP is generally more expensive than HDPE.

Polyethylene Terephthalate (PET): PET pallets are recognized for their dimensional stability, high strength-to-weight ratio, and corrosion resistance. They are impervious to moisture, liquids, and gases, and are highly recyclable.

Polyolefins: These pallets, made from a blend of HDPE, PP, and cellulose, are low-cost and highly rigid. They are ideal for one-way export pallets or in conditions where moisture is not a concern.

Fiberglass: Fiberglass pallets are strong, durable, and impact-resistant. They are also fire-resistant, making them superior to wooden and paper pallets in certain environments. However, fiberglass pallets tend to be more expensive.

For 3 Skids Plastic Pallets for Export, materials like HDPE, PP, and fiberglass are preferred due to their combination of strength, durability, and chemical resistance. These materials are capable of withstanding the rigors of international shipping and storage.

In summary, the selection of materials for 3 Skids Plastic Pallets is a crucial decision influenced by factors like plastic pallet price, recycling potential, and specific industry requirements. The choice of material directly impacts the pallet’s performance, sustainability, and overall cost-effectiveness in the supply chain.

Why Choose Enlightening Electromechanical for Your 3 Skids Plastic Pallet Needs?

Enlightening Electromechanical stands out in the industry by expertly manufacturing 3 Skids Plastic Pallets tailored to your unique requirements. We specialize in using premium materials like HDPE, PP, and fiberglass, shaping them into pallets that meet your specific needs.

Our team collaborates closely with you to provide customized solutions, focusing on your specifications. Our partnerships with top plastic pallet manufacturers ensure we deliver first-rate products.

Choosing Enlightening Electromechanical is more than selecting a product – it’s a commitment to excellence. You are guaranteed to receive plastic pallets that are not only of superior quality and durability but also reflect our dedication to sustainability and customer satisfaction.

Comparative Advantages of 3 Skids Plastic Pallets and 9 Legs Plastic Pallets

3 Skids Plastic Pallets:

- Durability and Load Capacity: Renowned for their exceptional strength, these pallets are designed to withstand heavy loads, making them ideal for robust handling and long-term use. This resilience is a crucial benefit for businesses seeking dependable solutions.

- Hygienic and Easy to Clean: Unlike wooden pallets, 3 Skids Plastic Pallets resist moisture and do not harbor bacteria or fungi. This feature makes them the preferred choice for industries where hygiene is paramount, such as food and pharmaceuticals.

- Eco-Friendly and Recyclable: As leading plastic pallet manufacturers, we ensure our 3 Skids Plastic Pallets are not only high-quality but also eco-friendly, aligning with modern sustainability practices by being fully recyclable.

9 Legs Plastic Pallets:

- Lightweight and Cost-Efficient: These pallets are designed for efficiency, offering a lightweight yet sturdy solution that reduces shipping costs. Their design facilitates easy handling and storage, making them a cost-effective option for various industries.

- Versatile and Safe Handling: The unique 9-leg design provides enhanced stability and safety during transport and storage. These pallets are ideal for lightweight and medium-duty applications, offering versatility across different sectors.

- Ideal for Export: Specifically crafted for export purposes, these pallets meet international standards and do not require treatments like fumigation, a common necessity for wooden pallets. This makes them a hassle-free, compliant choice for global trade.

Both 3 Skids and 9 Legs Plastic Pallets, produced by top-tier plastic pallet manufacturers, offer distinct advantages tailored to diverse industry needs. Whether it’s for heavy-duty applications, hygiene-critical environments, or cost-effective export solutions, our range of Plastic Pallets for Export ensures that your business needs are comprehensively met.

Industries Utilizing 3 Skids Plastic Pallets

3 Skids Plastic Pallets are increasingly being recognized for their utility across diverse industries, rivaling their 9 Legs counterparts in many aspects. While both types are crafted from HDPE Plastic Industrial Pallets and offered by numerous plastic pallet suppliers and manufacturers, they each have distinct features that cater to different needs within the industrial landscape.

- Automotive Industry: 3 Skids Plastic Pallets are utilized for their enhanced stability and support, particularly when double stacking heavy loads such as car parts and machinery. The three-skid design allows for a more even distribution of weight, which is essential when transporting delicate components that require additional care.

- Chemical Industry: The chemical resistance of HDPE Plastic Industrial Pallets is a shared advantage between 3 Skids and 9 Legs pallets; however, the skid version often provides better handling and storage capabilities in automated systems due to their structural design.

- Food and Beverage Industry: 3 Skids Plastic Pallets are preferred in scenarios where the ease of moving large stacks is crucial. Their compatibility with roller conveyor systems ensures that hygiene and contamination prevention standards are upheld during the transport of consumables.

- Pharmaceutical Industry: The non-porous nature and the ability to maintain cleanliness are vital in both pallet types. However, the 3 Skids design may offer better maneuverability within the controlled environments of pharmaceutical facilities.

- Petroleum and Lubricant Industry: For the transportation of jugs, drums, and other containers, the stability offered by 3 Skids Plastic Pallets makes them advantageous, ensuring that products remain secure during movement and storage.

Precautions for Handling and Use of Three Skids Plastic Pallets

Using Three Skids Plastic Pallets efficiently and safely is crucial in various industries. While some handling guidelines are similar to those for Nine Legs Plastic Pallets, the structural differences between the two necessitate specific considerations. Here are the best practices for handling Three Skids Plastic Pallets, crafted from HDPE Plastic Industrial Pallets and provided by plastic pallet suppliers and manufacturers:

Select the Appropriate Pallet: Choose a Three Skids Plastic Pallet based on its load capacity and compatibility with the goods you intend to transport or store. Different designs cater to different weight distributions and types of goods.

Inspect Before Use: Check for any structural damages like cracks or deformations. Clean the pallet to prevent contamination, especially important in industries like food and pharmaceuticals, where hygiene is paramount.

Optimal Stacking Method: Distribute the weight evenly across the pallet. Place heavier items at the bottom, ensuring stability. Utilize interlocking patterns between layers to minimize shifting during movement.

Load Securing: Secure the load with appropriate materials like stretch film or straps, ensuring the stability of goods without over-tightening, which might damage the pallet or the goods.

Proper Wrapping Techniques: Use durable wrapping materials that can support the weight and nature of the goods. Ensure thorough wrapping, covering the base, sides, and top of the pallet, with overlapping layers for added stability.

Adequate Storage: Store the Three Skids Plastic Pallets in a dry, clean environment away from direct sunlight and extreme temperatures. Proper storage conditions are vital to maintain the material integrity of HDPE plastic.

Avoid Overloading: Respect the maximum load capacity of the pallets. Overloading can cause structural failure and compromise safety during transportation or storage.

Handling Equipment Compatibility: Ensure that your material handling equipment, like forklifts or pallet jacks, is compatible with the three-skid design for safe and efficient maneuvering.

Regular Maintenance Checks: Regularly inspect pallets for wear and tear. While HDPE Plastic Industrial Pallets are durable, they can still degrade over time, especially under heavy use.

Environmental Considerations: As part of sustainability practices, consider the recyclability of the pallets at the end of their lifecycle and consult with Plastic Pallet manufacturers or suppliers about environmentally responsible disposal options.

By following these precautions, industries can maximize the effectiveness and lifespan of their Three Skids Plastic Pallets. These practices ensure that operations in sectors such as automotive, chemical, food and beverage, pharmaceutical, and others remain safe, efficient, and aligned with environmental standards. For more detailed guidance and options, reaching out to plastic pallets suppliers and manufacturers is advisable, as they can provide insights specific to your industry’s requirements.

Cleaning and Maintenance of Three Skids Plastic Pallets

The cleaning and maintenance of Three Skids Plastic Pallets, often used as stackable plastic pallets in various industrial applications, are crucial for ensuring their longevity and hygiene. Here is a comprehensive guide:

Manual Cleaning:

- Ideal for a small quantity of pallets.

- Start with an air compressor to remove dust, dirt, and debris.

- Wet the pallets with water (preferably under pressure).

- Clean using an industrial soap and brush.

- Rinse with water under pressure.

Steam Cleaning:

- Beneficial for killing all germs and bacteria, especially in pharma and food industries.

- Recommended temperature for steam cleaning is 80 degrees Celsius.

- This temperature is effective for germ destruction and safe for the pallets.

Automated Pressure Washer Machine:

- Provides the most thorough cleaning.

- Suitable for a large stock of pallets that need quick cleaning for reuse.

Sanitizing Routine:

- Consider using a sanitizer solution during cleaning.

- Effective sanitizing solutions include iodine, chlorine, quaternary ammonium compounds, and peracetic acid (PAA).

Cleaning Checklist:

- A consistent approach ensures best practices are followed.

- A typical checklist includes pre-wash (manual removal of large debris), wash, rinse, sanitize, and dry.

Do’s and Don’ts:

- Do: Use soft cleaning tools to avoid scratching the pallets, and ensure all cleaning agents are thoroughly rinsed off. Regular cleaning is recommended based on the frequency of use and environmental exposure.

- Don’t: Avoid using high-pressure jets that can damage the pallets, and refrain from using bleach or harsh chemicals that can degrade the plastic materials. Do not stack the pallets when they are wet or damp to prevent mold growth.

Adhering to these cleaning and maintenance guidelines will help ensure that your Three Skids Plastic Pallets, provided by plastic pallets suppliers and manufacturers, remain in top condition. This is particularly important for industrial plastic pallets used in sectors such as automotive, chemical, food, beverage, and pharmaceuticals. Regular and proper care of these pallets not only prolongs their life but also maintains the hygiene and safety standards required in these industries.

Applications of Plastic Pallets Across Various Industries

A unique variant of the highly popular HDPE Logistic Plastic Pallets, these pallets are indispensable in numerous industries thanks to their robustness and intelligent design. Offered by various plastic pallet suppliers and manufacturers, they are specifically adapted to meet the particular needs of different industrial applications

Export Activities:

Ideal for international shipping, compatible with logistic machinery, and suitable for inspection processes.

Food and Chemical Industries

Specialized models meet safety standards for hygiene and contamination control.

Warehouse Storage

Rackable pallets cater to heavy-duty storage needs with high load capacities.

Choosing the Right Plastic Pallets Manufacturer or Supplier

Selecting an appropriate manufacturer or supplier for plastic pallets involves several key considerations:

Industry Certifications: Ensure the supplier has relevant certifications like ISO9001 to guarantee quality and adherence to regulatory standards.

Product Range: Look for suppliers offering a diverse range of pallet types. This demonstrates their expertise and ability to cater to different industrial needs.

After-sales Support: Choose suppliers known for their robust after-sales service, as this is crucial for long-term satisfaction and resolving any potential issues.

Safety Standards: Verify that the pallets comply with safety regulations and industry standards, especially if your sector has specific requirements for hygiene, food safety, or hazardous materials handling.

Reputation and Reviews: Research the supplier’s reputation through customer feedback, reviews, and testimonials. This helps assess their reliability and quality of service.

Technical Expertise: Evaluate the supplier’s technical knowledge, which is essential in helping you select suitable pallets for your specific requirements.

Customization Options: Check if the supplier offers customization options to meet your specific requirements, whether for size, load capacity, or other specific features.

Transparent Pricing and Communication: Opt for suppliers who provide clear pricing and effective communication. This transparency is key to avoiding unexpected costs and ensuring a smooth procurement process.

Load Capacity and Durability: Consider the load capacity and durability of the pallets, especially if your operations involve heavy usage or harsh environments. This ensures longevity and maintains performance under demanding conditions.

Sustainability and Environmental Impact: Consider the sustainability and environmental impact of the pallets. Look for suppliers who use recycled materials and offer recyclable pallets, aligning with eco-friendly practices.

Sampling and Testing: Before a large-scale purchase, request samples and conduct tests to assess load capacity, durability, and compatibility in your specific environment. This step is crucial for making an informed decision.

By considering these factors, you can ensure that you select a plastic pallet supplier or manufacturer who can meet your specific needs, ensuring efficiency, safety, and sustainability in your operations.

Get in Touch

Submit Your Inquiry

Connect with us to discuss your plastic pallet needs. Our team is ready to provide solutions tailored to your specific requirements. Whether it’s a question about our products, a request for a quote, or a need for custom solutions, we’re here to assist you.

Elina You

- Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

- +86 18724763201

- sales03@cnplasticpallet.com